By: Dawn Zoldi

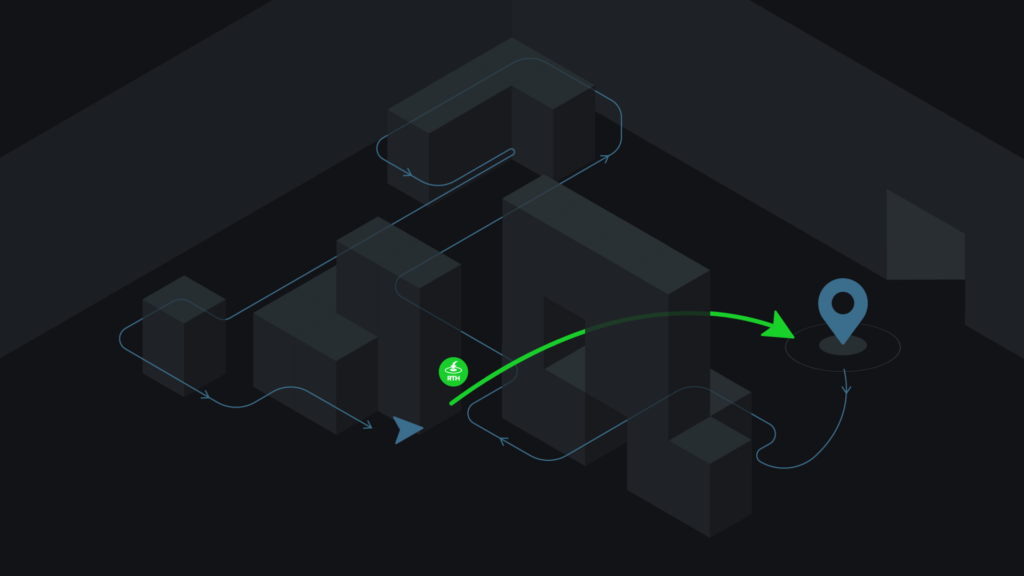

Remote drone inspections, especially in tight, GPS‑denied spaces, used to depend entirely on pilot skill and nerves of steel. Today, automation has changed what they look like. By shifting them from demanding, pilot‑driven missions into more predictable, data‑rich workflows that work across mines, factories and vast warehouses, smarter software and capable hardware work together to reach further, see more and keep people out of harm’s way.

From Hand‑Flown Missions To Guided Inspections

Early remote inspections depended almost entirely on pilot skill, especially indoors where GPS is unavailable and radio signals bounce or fade. Operators were expected to fly in tight spaces, manage signal quality, track battery life and still capture the imagery or 3D data needed for engineering decisions. In environments like silos, boilers and underground galleries, one distraction could mean a lost drone, or worse, a compromised safety margin.

Recent advances have changed that balance. Modern confined‑space inspection drones now combine collision‑tolerant frames, LiDAR‑based mapping and mission software that actively supports the pilot. Software now shoulders much of the navigation and safety workload while the human concentrates on what needs to be inspected, and why.

Case in point, Flyability purpose-built its Elios 3 drone for the places people should not go. It soars in GPS‑denied, dark, confined spaces where signal can be obstructed and spatial awareness is limited. With collision‑tolerant cages, LiDAR‑based mapping and cockpit software that shares a significant part of the burden, this drone enables pilots to concentrate on the inspection plan rather than fighting the environment. The aircraft remains a tool. The “work” increasingly happens in the way data is captured, safeguarded and processed after landing.

Safety Nets That Encourage Deeper Inspections

With tighter integration between its LiDAR, onboard computing and mission software, the amount of workload the system itself can carry continues to change. Elios 3 now layers in capabilities such as Smart Return‑to‑Home and Return‑to‑Signal, which watch over the mission in the background. This alleviates the need for the pilot to juggle navigation, data capture and safety at the same time.

For example, Flyability specifically built Return‑to‑Signal (RTS) automation for high‑risk indoor work. When the radio link degrades or drops, the Elios 3 automatically retraces its previous flight path for up to 300 meters and heads back toward the controller until video is restored or the take‑off point is reached. This behavior directly targets the realities of underground galleries, concrete shafts, metal tanks and other RF‑hostile environments where absorption and reflection can disrupt control without warning.

For pilots, this means signal loss is no longer synonymous with a lost drone or a dangerous rush to move closer to the asset in search of a better link. RTS lets them remain outside hazardous areas while the aircraft works its way back, even if the cause is something as simple as a drained radio battery, a loose USB cable or a crashed cockpit app.

Smart Return‑to‑Home (Smart RTH) takes this even further. It uses the Elios 3’s LiDAR‑based mapping and onboard algorithms to compute the shortest safe route back, instead of merely retracing its steps. As the drone flies, it continuously builds an internal model of the environment. It then uses this information to plan a direct path home when the pilot activates the feature or reaches an advisory threshold indicated by a flight‑time gauge.

That gauge, visible in the Cockpit app, clearly shows remaining flight time and the point at which Smart RTH should be triggered. This allows pilots to press deeper into complex assets without guessing how long the journey back will take. The result is more efficient use of each battery, less time spent planning “escape routes” and fewer aborted missions caused by conservative margins.

Data That Looks Like The Real World: Colorized 3D Models for Actionable Insights

Automation does not only bring the drone home. It also makes captured data far easier to interpret. The Elios 3’s new Colorization feature, released in December 2025, merges LiDAR point clouds with the drone’s video to produce textured meshes and colorized point clouds of indoor environments.

Monochrome LiDAR data can be powerful but demanding. It often requires specialists to match point clouds with video and field notes to understand what they are seeing. With colorization, surfaces in the 3D model look like their real‑world counterparts (think: walls, stains, markings, corrosion and targets). This allows managers, contractors and engineers to quickly understand asset conditions without being fluent in point cloud navigation.

Users report that this visual context makes measurements faster and more practical. They can visually identify features to measure directly in the mesh instead of manually syncing video timestamps. It also exposes details that LiDAR alone may miss, such as painted survey marks or other low‑reflectivity features that matter for georeferencing, deformation tracking or structural analysis. Because colorization runs in the Flyability Cloud, sharing a model becomes as simple as sending a link. It gives stakeholders an immediate “I get it” moment…even if they were not involved in the original mission.

Underground Mines: Pushing Deeper With Confidence

Nowhere is the impact of these capabilities more obvious than in underground mining, which has been one of the proving grounds for this new generation of automated inspection capabilities. In stopes, ore passes, and drawpoints, rock surfaces absorb radio energy, geometries twist unexpectedly and loose material can make manned entry unsafe or impossible. Elios drones are routinely flown into these areas, where rock walls absorb signals and irregular geometries turn navigation into a mental puzzle.

RTS reduces the risk of losing an aircraft around a bend or behind a rock pillar, which encourages pilots to explore further while still maintaining a clear way back. Smart RTH adds another layer. If battery time runs low at the far end of a stope, the Elios 3 can choose the most efficient route out based on its LiDAR‑derived map instead of forcing the pilot to manually retrace every turn.

Once back at the surface, colorized 3D models of rockfall zones or infrastructure give geologists and engineers a far richer view of conditions than point clouds alone. Feedback from operators shows that textured meshes help teams identify structural details, fixation points and deformation patterns faster. This translates into quicker decisions on support, remediation or access restrictions.

Warehouses and Factories: New Use Cases Emerge

The same automation that keeps Elios 3 safe in a mine is now opening entirely new use cases in modern industrial facilities. By replacing elevated platforms with drone flights, maintenance teams can inspect high and confined areas while remaining safely on the factory floor. This can cut risk and downtime at the same time. Elios 3’s indoor capabilities, including SLAM‑based LiDAR and thermal camera are key enablers for this kind of work inside production plants.

Jaguar Land Rover’s (JLR) Electric Propulsion Manufacturing Centre in Wolverhampton, UK, recently piloted the Elios 3 for internal inspections and documented dramatic improvements. Inspection time dropped from four hours to ten minutes…a whopping 95 percent reduction.

Following this success, JLR’s Logistics Operations Centre in Solihull, a warehouse complex roughly equivalent to thirteen football pitches, is testing Elios 3 for inventory management. In this environment, the drone is equipped with barcode scanners to automate stock checks, replacing manual processes and supporting faster, more accurate updates on inventory levels and locations. The combination of indoor flight performance, autonomy features and rich data capture turns Elios 3 into a mobile sensor platform that can repeatedly navigate large indoor spaces without scaffolding, lifts or extensive floor disruption.

What’s Next: Automation As A Platform

Many of these automation advances ride on software that can evolve faster than the airframes themselves. Smart return behaviors, flight‑time guidance and colorization are all steps along a longer roadmap aimed at making indoor and confined‑space flights more automated, more predictable and easier to interpret. Flyability explicitly describes Smart RTH as only the first phase in its roadmap toward even more automated inspections.

Colorization, delivered via Inspector Online with unlimited credits for subscribers and trial credits for free users, shows how processing and visualization capabilities can evolve independently from the hardware and instantly upgrade the value of existing flights.

As new capabilities roll out, some announced on subscription plans, others as cloud‑based processing upgrades, they not only improve new missions but also increase the value of data that has already been collected. A dataset captured months earlier can gain new utility once processed with updated pipelines, delivering more insight without sending a pilot back into a hazardous environment.

With another round of automation‑focused developments expected to launch in February, each software release aims to further reduce pilot workload, improve safety nets, and turn raw inspection data into actionable insight faster.

The trajectory points toward inspections evolves remote inspections from merely flying a drone to running a mature industrial workflow:

- Define the objective

- Launch the platform

- Let built‑in behaviors handle the hardest parts of navigation and safety and

- Work with rich, intuitive 3D models that mirror the real world.

In practice, this means that every Elios 3 mission, whether it is mapping a hazardous stope, checking beams in a factory or scanning racks in a warehouse, benefits from a growing toolkit of automated behaviors and smarter analytics.

Software and hardware will continue to evolve together. In that future, automation provides that critical layer which turns remote inspection from a specialist art into a reliable, scalable part of everyday operations.