By: Dawn Zoldi

ScoutDI, a standout in the drone technology sector, has swiftly established itself as a global leader in digitalized inspections of industrial confined spaces. With the third iteration of its flagship Scout 137 drone, the Norwegian company does not merely address inspection pain points but also sets a benchmark for data-driven asset management and workplace safety

Academic Origins, Leaders and Big Impacts

ScoutDI’s roots are woven into the innovative fabric of Trondheim’s Norwegian University of Technology and Science. The company began as an outgrowth of advanced Ph.D. projects focused on robotics and cybernetics, with a mission to give industry access to safer, more cost-effective methods for inspecting hazardous, GPS-denied environments.

Eivind Sivertsen, the company’s Marketing Director who brings over 20 years of experience across semiconductors, IoT, and robotics to the table, and Håvard Eilertsen, the company’s Chief Commercial Officer, renowned for his 15-year track record in sales and strategic leadership at notable firms like Autronica and Enua, represent the team leading the company’s commercial efforts. Sivertsen brings a mastery of both technical and marketing challenges, leveraging a background in application engineering and product training before transitioning to drone enterprise leadership. Eilertsen, meanwhile, channels his knowledge from fire and gas detection sectors to steer ScoutDI’s business evolution.

Originally named Scout Drone Inspection, the firm shifted its name to ScoutDI to avoid any confusion that it provided inspection services. From day one, it was always about developing robot technology, according to Siversten: the hardware, software, and cloud engines that now comprise its holistic inspection ecosystem. Now, seven years later, ScoutDI has unleashed its third generation tethered industrial drone and created an entire ecosystem around it for end-to-end asset inspections.

Third Generation: What Sets the Scout 137 Apart

ScoutDI’s Scout 137 Drone System represents another achievement in line with the company’s philosophy: keep improving based on user feedback, conduct practical field trials and leverage the continuous influx of new technology.

“There’s no doubt that when you launch the first product, the market will be all over it and give lots of feedback, and you see there are things we can do better,” said Sivertsen. “With the Gen 3 now, we have for example the 128-beam LiDAR as a standard component, and there’s the new UTM Payload…so we kept refining the concept of tethered, Lidar-based inspection drone and this is the state of the art right here.”

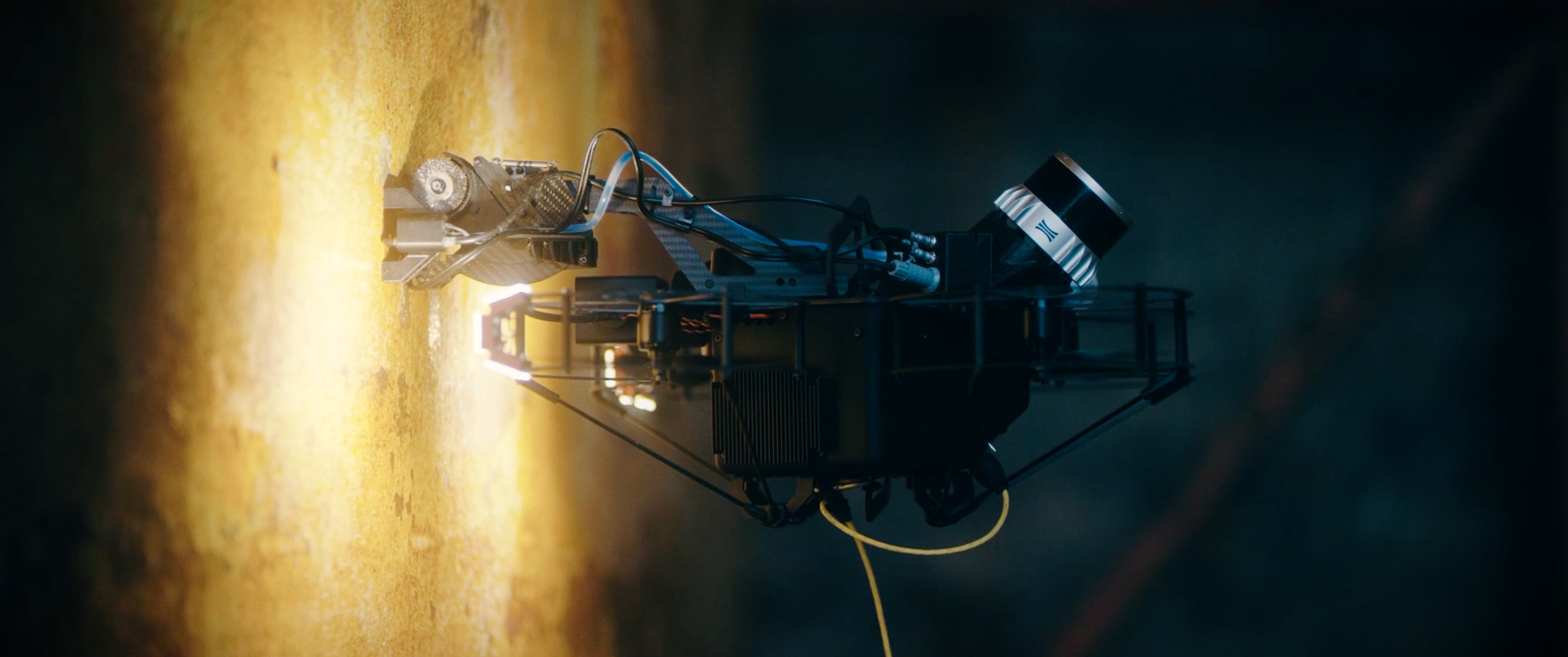

The ScoutDI team has meticulously engineered this new version of the Scout 137 specifically for the inspection of tanks, silos, tunnels and cargo holds—spaces where GPS coverage is absent and risks to human inspectors spiral. It operates entirely through a Kevlar-reinforced tether connected to a ground station.

Eilertsen explained how the tether confers real benefits: tether-first designs allow unlimited flight time, more full-spec payload capacity and a fully wired path that bypasses the link uncertainty challenges of wireless systems. “It eliminates some serious distractions, enables several efficiency factors and allows full focus on the job,” he noted.

One Drone, Many Capabilities

The chassis of the Scout 137 has evolved to be both rugged and resilient, specifically to handle industrial conditions. At its core lies a survey-grade, 128-beam LiDAR, twice the beam density of its predecessor, crucial to generate precise 3D point clouds, enable real-time SLAM (Simultaneous Localization And Mapping) and provide the operator with a real-time accurate spatial map, even when piloting beyond visual line of sight (BVLOS).

“The LiDAR also gives us location-tagged data and allows us to build point clouds which can be used to develop digital twins, 3D models, for measurements,” Eilertsen explained.

The drone’s camera system is another leap: a 3.5x optical zoom unit with autofocus can scrutinize hard-to-reach places. It ensures sharp, high-resolution imagery even around obstacles or from a safe distance. Lighting exceeding 12,000 lumens supports imaging in the darkest storage tanks, while the stabilized 4K video output ensures inspection footage is actionable.

Another built-in and standard payload is a multi-gas sensor. It provides early warning against flammable or toxic gases by detecting multiple hydrocarbon variants during flights. “Its there, since we’re flying in toxic environments, to give you a warning…if it detects gases,” Eilertsen said. The operational value of this feature alone for the oil, gas, maritime and chemical sectors, where compliance and safety are paramount, cannot be overstated.

The Game-Changer: UTM Payload With Integrated Cleaning

If we had to choose just one breakthrough innovation in the Scout 137 Gen 3, it would be the full-spec UTM Payload (Ultrasonic Thickness Measurement). It not only measures, but also prepares, surfaces for inspection…as an all-in-one feature.

Traditionally, UT measurements required field personnel to clean a surface, apply couplant gel, and then use manual gauges or robots to assess steel thickness. In the harsh, dirty environments typical of oil and gas or maritime assets, this was time-consuming, dangerous and often produced poor or incomplete data.

With ScoutDI’s approach, the UTM payload uses a motorized brush-and-probe assembly with magnetic hold-down. “We have several probe types for different use cases,” said Sivertsen. “The arm tilts to multiple angles so you get solid coupling to the surface, whether it’s vertical, horizontal or something in between. The cleaning tool works like a small grinder, and you can swap in different brushes to clean the surface properly without damaging it.”

The brush removes accumulated grime, rust or hydrocarbon residues, further increasing the ability to make accurate ultrasonic measurements without human entry. The upshot is not just data quality, but a dramatic reduction in inspection time and risks. “The fact that you can do cleaning and measurement with the same tool means you’re cutting the inspection time for this type of job in half, or more,” Sivertsen asserted.

Driving the Digital Inspection Revolution

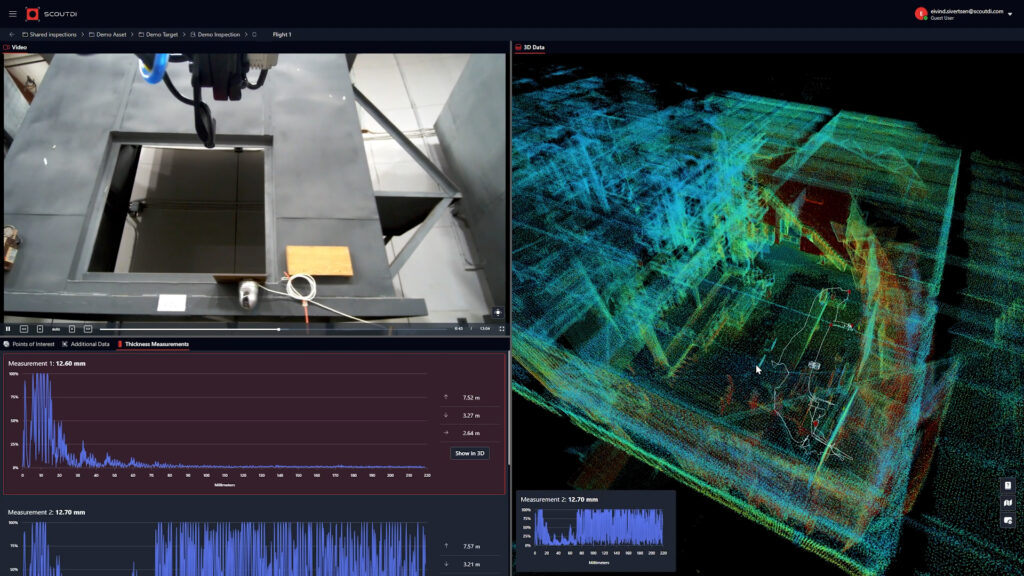

Beyond the Drone System, ScoutDI provides the Scout Portal: its cloud analytics layer. The Portal fuses 4K visual data (video and photos), LiDAR point clouds and UT measurements into one dataset and preserves the drone flight path with all points of interest and UTM points mapped along it for review, annotation, and reporting, minimizing reliance on third-party software.

Why does this matter? It gives maintenance planners and asset owners a single, unified lens with which to evaluate asset condition. “Everything is in one place,” said Sivertsen. “The platform shows all multimodal data in context with the flight path and synchronized to the video timeline, so everything is tied to a specific time and position inside the asset”.

Users can even live-stream inspections remotely, which reduces the need for travel and enables subject-matter experts to participate virtually, in real time. “You could live stream what you’re doing directly to an inspector’s desk. That’s really a value creator,” Eilertsen noted. For example, data from an onboard ship inspection while the vessel is afloat can be sent ashore to stakeholders for their review.

Always Iterating: What’s On the White Board

ScoutDI’s ethos is rooted in listening intently to user experiences and evolving accordingly. “We tend to listen a lot to people in the field, go on field missions and take part in research projects…to find out what [they] need… not just what is the next step, but how can we give the guys what they need,” Sivertsen explained.

This customer-centric innovation cycle has led to a steady tempo of upgrades. Even with the release of the Gen 3 Scout 137, the team is already actively considering new features and user-driven requests. The ScoutDI team appears to never rest, relentlessly focused on making each generation of the Scout 137 more capable and easier to use for complex inspection scenarios.

Scouting for Enterprise: The Enterprise Value in Inspection

ScoutDI has redefined the economics and safety calculus of industrial inspections. By consolidating inspection tasks, data management and safety precautions into a single, streamlined system, companies can spend less time and money on scaffolding, rope-access teams and risky manned entry. More critically, operators now have access to location-tagged, actionable data—a win for planning, compliance and proactive asset management.

ScoutDI offers a cohesive answer to the confined inspection space: a robust, integrated system that empowers enterprises to scout, analyze and act with confidence. From its academic roots to the relentless dynamic tweaks on its white board, ScoutDI symbolizes the new enterprise frontier in digital inspection.

Watch Eivind Sivertsen and Håvard Eilertsen on the Dawn of Autonomy Episode 89.