By: Dawn Zoldi

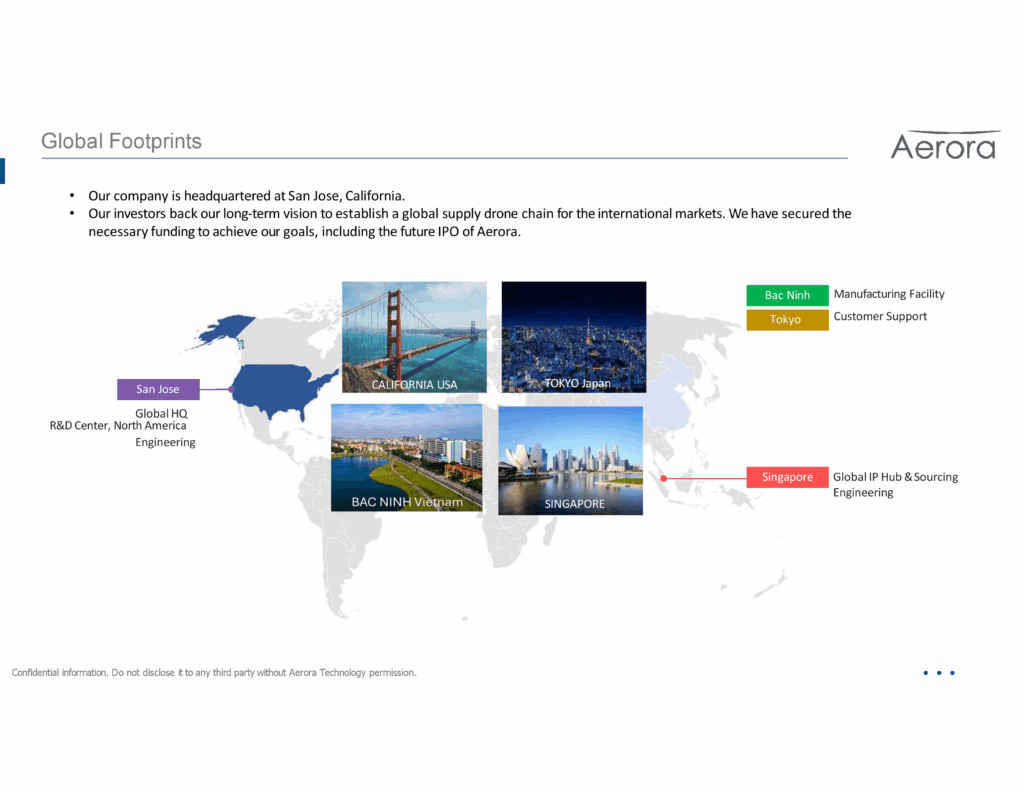

In the drone industry, where speed, compliance and reliability remain the lifeblood of progress, Aerora pushes drone and robotics technologies to new heights. From its U.S. headquarters in San Jose, California, Aerora is shaping the global supply chain for drone OEMs. Meet this company, which pushes the boundaries of what NDAA-compliant platforms can do, and helps partners accelerate time to market without sacrificing safety, performance or trust.

Phil Mann: Driving Aerora’s Global Mission

Phil Mann, Chief Commercial Officer, who stands at the helm of Aerora’s commercial vision, has a career arc that mirrors the company’s pragmatic, results-driven ethos. Mann launched his tech journey honing position, navigation and timing (PNT) systems, essential for anything that moves without human input. One of his milestone projects involved boosting the throughput of the New York City subway system by leveraging deep technical know-how for true real-world impact.

Mann’s foray into drones crystallized during a stint at Yuneec, where he positioned the company as a key player in enterprise-grade uncrewed systems. “Everything I’ve done has been about enabling and increasing productivity. Now, at Aerora, that’s what we deliver: market acceleration for these amazing tools,” Mann explained.

Aerora Worldwide: From Roots in Vietnam to Santa Clara Success

Aerora’s ascent is grounded in a unique east-meets-west story. The company has its factory in Vietnam, a stalwart manufacturer of electric speed motors and controllers, where it applied its expertise in volume production. “We’re now making tens of thousands of motors at a time,” Mann noted.

This foundation laid the groundwork for a global trajectory. Strategic growth brought Aerora to the U.S. west coast, with additional technical operations in Portland, Oregon, as well as sales and partnerships extending into Japan and reference designs out of Shanghai.

At each step, the company’s focus has been clear: empower OEMs and enterprise clients to go from concept and prototype to full-scale, NDAA-compliant manufacturing, regardless of order size or complexity.

The Mission: Speed, Quality and Trusted Partnership

Aerora’s ethos is simple but powerful: accelerate time to market for partners by delivering top-tier supply chain, integration and engineering support.

In today’s competitive landscape, drone OEMs face relentless pressure to deploy new features, whether high-res thermal sensors or robust propulsion systems. “If you’re a drone OEM and you need the latest and greatest camera for your fleet, Aerora can integrate and engineer that solution and fast-track your rollout,” Mann asserted.

By providing engineering integration alongside a nimble, in-house supply chain, which spans small batches to mass production, Aerora allows innovators to focus on user experience and mission outcomes, not logistics headaches.

Aerora’s client portfolio reads like a who’s who of the drone world, but Mann was quick to highlight the “white label” and bespoke options that make the company attractive to both established names and ambitious startups. Whether it’s retrofitting existing fleets or designing custom hardware for niche applications, the goal is to become more than a manufacturer. Aerora aims to become a strategic technology partner built for the speed and complexity of UAV growth.

End-to-End Expertise: Propulsion, Data Links, Ground Control, Gimbals, Batteries

A commitment to mastering the entire drone ecosystem, not just one flashy feature, truly sets Aerora apart.

Motoring…What’s Your Price for Flight?

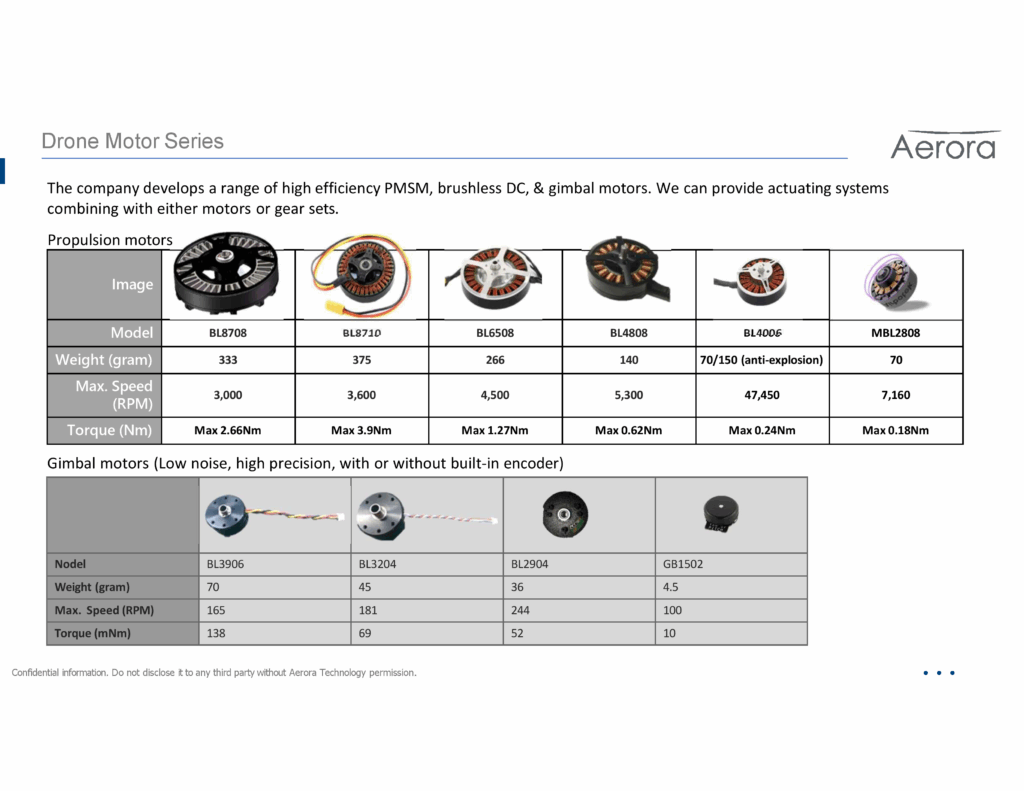

At the propulsion level, Aerora’s advanced electric motors, with roots in Vietnam’s robust factory operations, leverage electromagnetic and thermal analysis to surpass industry norms. The company builds in metrics like low noise for regulatory compliance, power delivery and tailored profiles for specific mission types from the design stage, with the ability to collaborate and iterate for unique customer needs.

It’s All About The Data

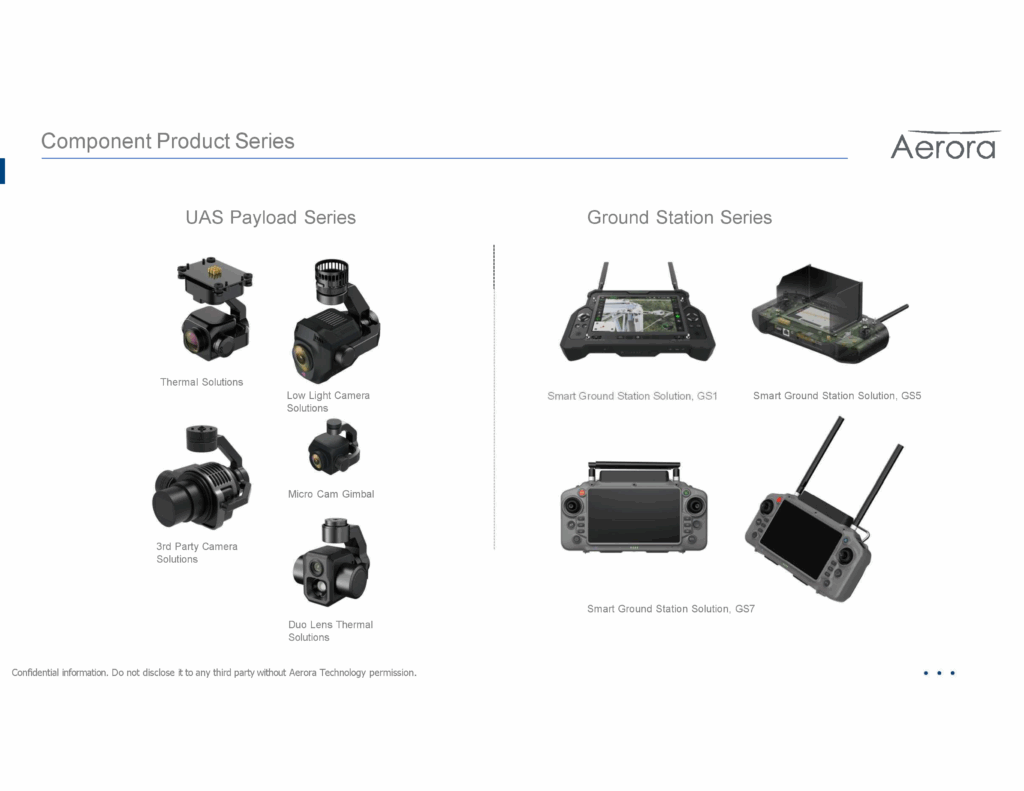

One of the core offerings revolves around remote data links and ground control stations (GCS). Aerora’s third-generation GCS represents pilot and customer feedback. Android-based, with advanced dual-band LTE and customizable hardware configurations, these systems deliver field-ready edge compute and seamless integration. “Our ground control stations are built with the realities of the field in mind, combining swappable battery packs and robust anti-interference tech for security and uptime,” Mann said.

Carrying the Load

Aerora’s payload expertise is equally rigorous. It offers a modular, NDAA-compliant lineup of camera payloads, current RGB plus thermal, extending to lidar, laser rangefinding and multispectral imaging options, all powered by next-gen Qualcomm processors.

Its gimbal systems, also built on proprietary motor technology, cover a spectrum form plug-and-play to bespoke, ensuring that price-performance benefits flow directly to end-users. According to Mann, “The real benefit is efficiency and price-performance, with integration that’s smooth for both small and large fleets.”

Flexibility Is the Key To Airpower: NDAA Compliance Plus Accomodation

Aerora’s story intertwines with the pressures of NDAA compliance and the shifting sands of American and global regulation. Having set up its manufacturing playbook with compliance in mind, Aerora’s process weaves together Vietnamese manufacturing for scale and flexibility with U.S. final assembly and quality control in Portland or San Jose. Its GCS, for example, is in the process of getting AUVSI “Green” approval, after already having satisfied multiple layers of NDAA self-certification.

“We started with NDAA compliance as a core premise,” Mann explained. “It’s never easy, but our diversified supply chain, combined with rigorous process discipline, means we can deliver the quality and reliability our defense and public safety partners require, while meeting the evolving U.S. regulatory picture head-on.” If a client requires certain non-foreign components, the company can accommodate that. If the client can leverage the high quality and cheaper foreign components, the company can do that too.

Better Together: OEM Partnerships to Build a Dynamic Industry

Aerora takes a deeply collaborative approach, working with sensor manufacturers like Teledyne FLIR and Lantronix, communications specialists and OEMs to create tailored solutions that meet sector-specific performance and compliance needs.

Sensor integration, white-label hardware and advanced SDKs make for seamless development cycles and shortened engineering lead times. Mann framed it, “You win in your market if you can integrate quickly and scale confidently. Aerora’s done the groundwork so our partners don’t have to reinvent the wheel.”

The company’s focus on partnerships extends globally. Aerora’s customer profile includes both fast-rising OEMs seeking robust standard parts and major corporations needing custom builds for critical infrastructure inspection, public safety, energy, agriculture and more. The company’s value proposition applies whether the customer is managing inspection fleets for utilities or visioning next-gen robotics for tightly regulated use cases.

What’s Next for Aerora: Enabling More Missions In 2026 and Beyond

Aerora has shaped its future vision with the same ethos that propelled its rise: tighter integration, broader compliance and expanding value through modular, interoperable systems.

The company’s future efforts will likely focus on advanced, high-resolution camera payloads, expanding mesh networking and cybersecurity features and pushing toward the “Lego” model of drone hardware, where drone and robotics platforms are even more customizable, scalable and easy to augment with new applications or sensors.

As Mann looks to the future, he stressed the continued blend of speed and substance. “The industry’s been talking about inflection points for years, but we’re finally seeing beyond visual line of sight become a reality for many missions. Our job at Aerora is to make sure the hardware keeps up by delivering compliant, robust, and easy-to-integrate solutions for partners on the front lines of this evolution,” he noted.

Last Call: Collaborators Welcome!

For innovators with solid technology or visionary clients, now is the time to team up with Aerora. “We have the platforms, the supply chain, and the engineering prowess to take your ideas from concept to scale faster, safer, and with full compliance,” Mann said.

Aerora’s doors are open to sensor companies, distribution partners and OEMs of all sizes ready to realize the sum that is greater than its parts.

To connect or learn more, visit Aerora’s website or seek out Phil Mann at major events and conferences in the coming year. Mann and the entire team at Aerora welcome collaboration. After all, it is the foundation of Aerora’s approach.

Watch Phil Mann, CCO of Aerora, on Episode 92 of the Dawn of Autonomy Podcast.