By: Juan B. Plaza, AG Operational Safety Ambassador

The Commercial UAV Expo 2025 panel “How Real-World Efficiencies Are Being Enabled by Drone-in-a-Box (DIB) Solutions” showcased autonomous DIB solutions and highlighted how these systems deliver tangible efficiencies across various industries, especially now that flights beyond visual line of sight (BVLOS) are around the corner.

Unlike traditional drone operations, DIB deploys automated units that seamlessly collect, analyze and integrate data without the constant presence of a human pilot. DIB doesn’t exist in traditional aviation. It’s one of the few things that is completely separate and independent. This distinction marks a pivotal advancement in aerial workflow, one poised to redefine the standards of automation and remote monitoring in enterprise settings.

Docked Drone-as-a-Service: FlytBase’s Achal Negi on Infrastructure and Integration

Achal Negi, Director of Business Development at India-headquartered FlytBase, traced his journey from robotics to the heart of autonomous drone infrastructure. Negi introduced the critical concept of Docked Drone-as-a-Service (DaaS), a model moving beyond the travel, cost and training hurdles of traditional drone services.

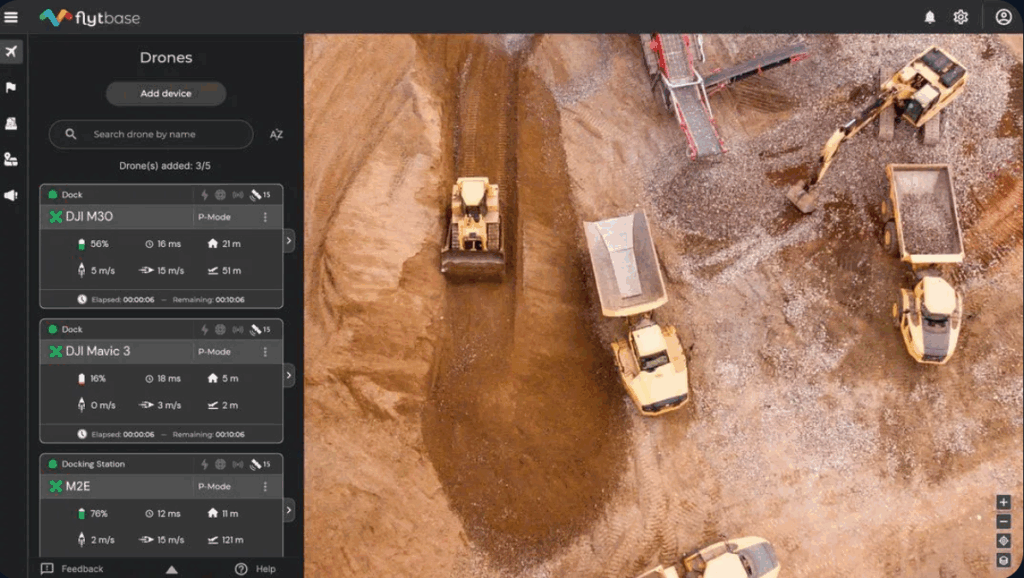

Negi emphasized, “We used drones as just tools… What is changing is the… box systems or docked drones…are used as part of the infrastructure.” With deployments in sectors ranging from power utilities to mining, ad hoc data collection has transitioned to fully integrated, site-wide autonomy. FlytBase clients, such as energy providers in Norway that manage over 11,000 kilometers of power line and 50 substations, have realized the advantages firsthand. “They deploy automated drones on their site. Anytime they want to do a scheduled inspection, they arrange for a slot throughout the day. The drones fly on a continuous basis, capture that data and send that data back to the processing pipeline,” Negi explained.

Mining sites and rail yards which proved challenging for manual inspection historically, now employ autonomous systems that scale across thousands of miles and hundreds of vehicles. One compelling case involved Anglo American mining operations, where autonomous drones inspect blast areas prior to detonation. The integration allows real-time checks for personnel and assets that reinforce safety. Negi added, “As soon as a truck is back in, there’s a need to inspect it, and the drone can do that. These trucks are huge… So we manage that entirely integrated with their systems.”

Yet, Negi made it clear that success demands more than hardware. “Remote flying is not equal to dock drone ops. It’s not just about flying the drone. It’s about integrating that system… It’s about solutions that help them integrate with their existing solutions,” he said.

The future, he predicted, lies in solutions that fuse drones with ERP (Enterprise Resource Planning) platforms, security systems and city-wide command centers. In the case of urban deployments, as in Ashland, North Carolina, a network of 30 docking stations provides uninterrupted surveillance and rapid response, a testament to the scalable potential of docked drones.

Overcoming Hardware and Compliance Challenges: Exabotix’s Julian Ederleh

Julian Ederleh from German company Exabotix GmbH further explored the technical journey of DIB solutions. With roots in custom industrial drones and a focus on serial production, Ederleh outlined how his team built a fully automated DIB system, DRONEPORT, as an alternative to costly helicopter inspections.

“Our colleagues developed the first droneports, which looked kind of like a shipping hangar… We had two of these systems deployed along the pipeline,” Ederleh recalled. “These initial prototypes enabled long-range flight, essential for inspecting gas pipelines that spanned vast distances. However, hardware reliability and regulatory compliance presented obstacles.” Ederleh shared, “When it rained heavily, these container-like structures leaked inside and we didn’t really know where it came from. Opening and closing was unreliable and we needed somebody on site.”

“Achieving European Union (EU) approval for fully autonomous, BVLOS operations demanded robust safety mechanisms, especially preflight checks for remote deployments.” Ederleh added.

To overcome these hurdles, the Exabotix team implemented advanced camera systems for preflight verification and weatherproofing. “We developed this custom camera system, which is approved now for BVLOS in Europe in 2024. I think we were some of the first to legally go from port to port,” said Ederleh. “The resulting DRONEPORT 2, a more compact unit compatible with fixed-wing drones and multicopters, can fly over 120 kilometers per mission and operate reliably in rough climates.”

In order to scale deployment, Exabotix now services not only energy providers but also sectors such as perimeter security and agricultural inspections. Ederleh emphasized: “We were able to cut the cost significantly for perimeter and pipeline inspections, replacing helicopters and scaling up across the whole network.” Residents along long pipeline routes, he noted, benefit from less noise and increased safety. As DIB hardware matures, Exabotix’s story underscores the importance of iterative engineering and close collaboration with regulatory agencies.

Expanding on Multi-Mission Drone Dock Networks: Insights from Aaron Zhang, A2Z Drone Delivery

Aaron Zhang, Founder and CEO of A2Z Drone Delivery, brought the session home with a compelling look at multi-mission drone dock networks, systems that extend far beyond single-purpose patrol or delivery. Zhang’s company designs unique docks that eliminate mechanical moving parts and, as such, address a persistent point of failure. “The problem with drone-in-a-box solutions is that they’re highly mechanical… People spend more of their time fixing the drone in the box than actually using it,” Zhang asserted, drawing on experience at DJI.

A2Z’s central innovation: to use elevated, static air docks where drones autonomously land, recharge and deploy for various tasks, from waterway patrol to medical delivery. The company’s network in China, developed and validated over two years, covers diverse villages and towns with permanent and portable solutions for all-weather endurance. Zhang described operational efficiency: “We’re flying 20 missions per day and cover around 500 kilometers per week. In the next phase, by Q1 of next year, we’re going to be covering the size of L.A., with 20 drones and 35 docks in service.”

These multi-use networks serve as critical infrastructure for missions including search and rescue, environmental monitoring and public safety. Zhang offered a real example: “Whenever there’s a situation such as a drowning person, then a remote pilot can manually take over and winch down the life preserver.” In healthcare, drones deliver surgical tools or blood samples between clinics and hospitals. In environmental conservation, they patrol for water pollution and wildlife crime.

The company’ approach emphasizes shared infrastructure, scalable deployment and operational flexibility. According to Zhang, “Drone infrastructure is better when it’s shared for new projects, it’s easier to lead with the must-haves such as public safety and then follow with nice-to-have apps such as pizza delivery.”

The modularity of the docks means drones can quickly shift from one type of mission to another, which maximizes return on investment (ROI) and utilization. This model, Zhang argued, mirrors the public utility of roads, designed for long-term investment and wide public benefit. “The system’s reliability” he stressed, “depends on the simplicity and robustness of design as well as extensive pre-deployment testing.”

Addressing Technical Challenges and Data Management

The panelists converged on several common challenges facing DIB solutions: reliability, environmental resilience, ROI tracking and data management. Negi summarized, “You need that 99.999% kind of reliability with these systems to work. You need to do a lot of testing.” Whether dealing with thermal extremes in Las Vegas or hardware failures in remote Europe, robust design and extensive flight testing remain core strategies.

Data management emerged as another defining issue, both during and post-flight. Zhang highlighted network synchronization and mesh radio communications as vital for real-time mission coordination during missions. Back in the office after the mission, operators must handle the exponentially higher volumes of log files, image data and analytical outputs that result from autonomous flights. Negi noted, “You are connecting ten times the data now because these systems are already busy and continuously flying.” The key, he said, is building AI-assisted analytics to synthesize actionable insights from terabytes of raw footage and sensor streams. Zhang also highlighted network synchronization and mesh radio communications as vital for real-time mission coordination.

Compliance, especially for BVLOS flights in critical infrastructure zones, demands collaboration with aviation authorities and continuous attention to fail-safe protocols. Weatherproofing, battery health, mechanical redundancy and autonomous troubleshooting also become increasingly important as companies move toward unmanned, distributed deployments.

Emerging Applications: From Urban Security to Remote Pipelines

Case studies presented throughout the panel revealed the broad versatility of DIB systems. Negi observed, “One of the approaches we have seen our partners taking is the low hanging use cases, so they tackle these where the drone can be flown 24/7 first.”

In North Carolina, Flytbase-powered docked drones oversee urban zones, respond to incidents via integrated alarm systems and provide rapid situational awareness to first responders. Mining operations in South Africa and Latin America use autonomous drones to monitor blast areas, inspect assets and coordinate with ERP software for logistics. Agricultural sites in the Philippines combat theft and optimize yields through continuous, automated patrols.

Exabotix demonstrated pipeline monitoring at scale, showing how automated drone ports can substitute helicopter flights, mitigate environmental impact and deliver high-frequency surveillance over thousands of kilometers.

A2Z’s multi-mission dock network operations include water pollution detection, search and rescue in recreational waterways, thermal night patrols for wildlife preservation,and precision delivery of medical samples.

The evolution toward shared infrastructure creates new business models as public agencies invest in the base network, while private and institutional users purchase contracts to access services. This mirrors the evolution of road and utility networks.

Looking Forward: From Tools to Infrastructure

Throughout the panel, speakers returned to the broader theme: DIB technology continues to shift drones from specialized tools into the realm of enduring infrastructure. The future points toward networks of autonomous drones, integrated with enterprise and city management software, capable of delivering high-value services at scale and with minimal human oversight.

Drawing lessons from aviation history, this phase mirrors like the leap from piston engines to the jet era, a moment when new technology unlocks broader markets and operational paradigms. The challenge now is to translate technical advances into sustainable, revenue-generating solutions. Industries must move beyond one-off deployments to shared, cross-functional networks that deliver cost efficiencies, scalability, and enduring reliability.

The Commercial UAV Expo 2025 panel illustrated the practical transformation underway in the world of autonomous drones. Achal Negi, Julian Ederleh and Aaron Zhang articulated not only the state-of-the-art in DIB technologies but also the operational, engineering and strategic challenges that lie ahead. As organizations increasingly recognize drones as foundational infrastructure, these insights can help inform the next wave of innovation, integration and market growth in autonomous aerial workflows.